(EN)

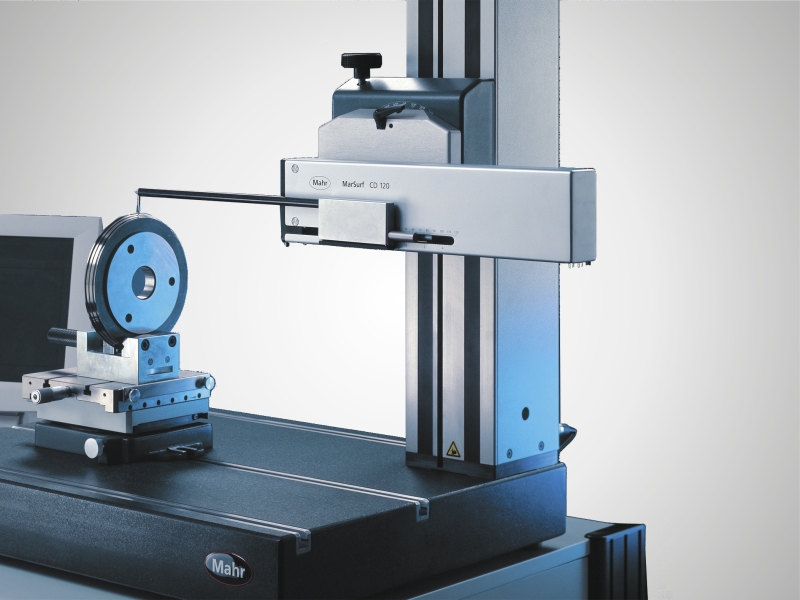

Your entry into precision contour measurement

- The quick, simple and inexpensive 2D contour measuring system satisfies all demands in terms of accuracy and range of evaluation criteria

- Consistently delivers safe and reliable results

- Pparameters that are dependent on datum elements are recalculated as soon as a datum element is changed

- Password protected user access prevents improper use

- Outstanding calibration processes including geometry calibration, measuring force calibration, bend compensation, etc.

- Sturdy, rigid probes

- Smooth running, sturdy and accurate drive unit

- Automatic lowering and raising of the probe arm at individually adjustable speeds

- Patented probe arm attachement for collision protection

Applications

Machine building

- Bearings, threads, threaded rods, ball screws, shafts, racks

Measurement close to the production area

- Contour measurement in semi-automated operation

Automotive industry

- Steering, brake system, gearbox, crankshaft, camshaft, cylinder head

Medicine

- Contour measurement for hip and knee endoprostheses

- Contour measurement for medical screws

- Contour measurement for dental implants

Accessories

Optional:

- Parallel vise, vee-block

- Equipment table

Software options:

- DXF import option

- Tangential elements option

- QS-STAT / QS-STAT Plus option

Shipment

- MarSurf XC 2 including PC, MidRange Standard, MarSurf XC 2 software, Mahr license key

- TFT monitor

- MarSurf CD 120 drive unit

- MarSurf ST 500 measuring stand (including holder)

- Calibration set

- MCP 23 manual control panel

- CT 120 XY table including rotary adjustment