(EN)

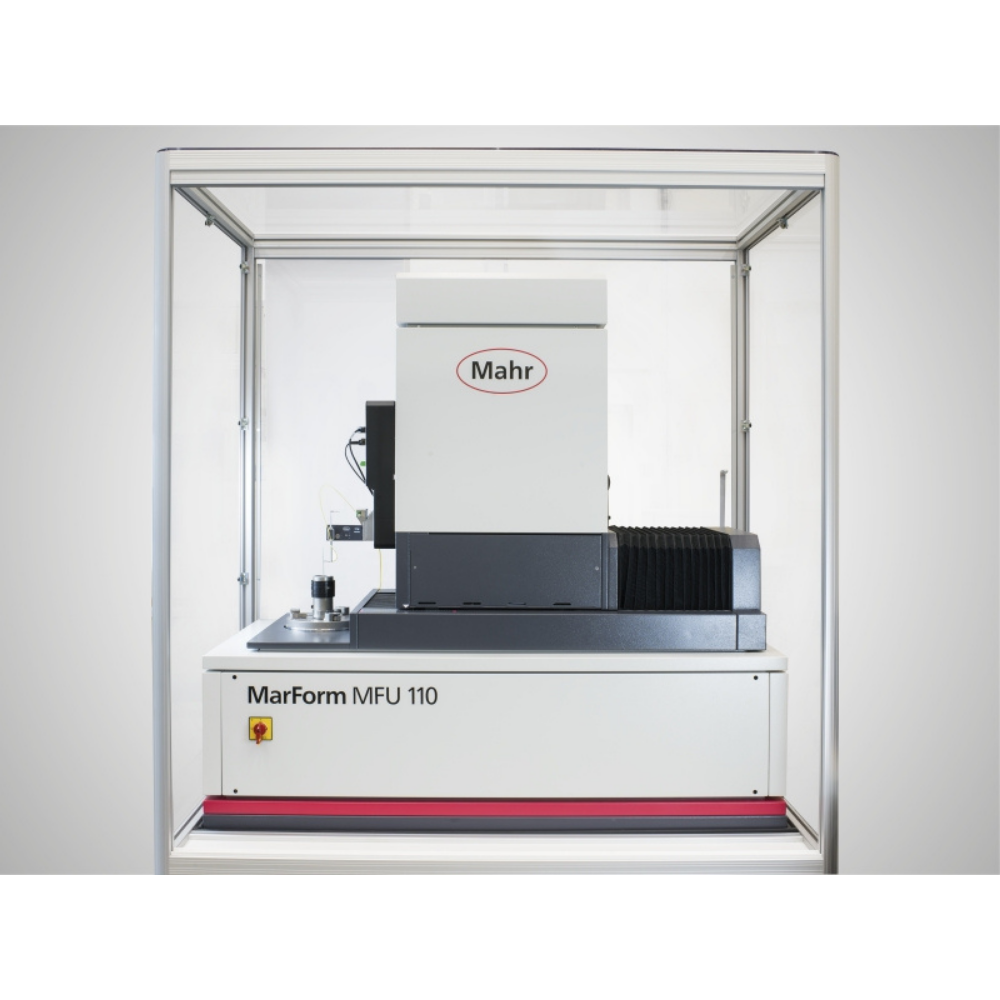

Reference form measuring machine for fine measuring room and production with tactile and optical sensors.

- Make the most of the advantages the latest optical measurement technology has to offer

- Contactless form measurement of sensitive parts

- Particularly high measuring accuracy

- Reduction of your production costs

- Direct use in production

- Maximum level of automation

The high-precision MarForm MFU 110 measuring machine is based on the tried and tested MFU 100 with the addition of a high-speed C-axis. The highly flexible MarVision IPS 15 optical measuring system is optionally available. It is a tactile and optical probe for high-precision measuring tasks in measuring rooms or in production.

Uzdot jautājumu

Technical Data

|

Roundness deviation (µm+µm/mm measuring height) *

|

0,01 + 0,0002

|

|---|---|

|

Roundness deviation (µm+µm/mm measuring height) **

|

0,02 + 0,0004

|

|

Axial runout deviation (µm+µm/mm measuring radius) *

|

0,02 + 0,0002

|

|

Axial runout deviation (µm+µm/mm measuring radius) **

|

0,04 + 0,0004

|

|

Centering and tilting table

|

automatic

|

|

Table diameter (mm)

|

180

|

|

Table load capacity, centered (N)

|

200

|

|

Speed (rpm) 50 Hz / 60 Hz

|

0.1 to 200

|

|

Straightness deviation / 100 mm measuring path (µm)**, Z axis

|

0.1

|

|

Straightness deviation / total measuring path (µm)**, Z axis

|

0.3

|

|

Parallelism deviation Z-/C axis in tracing direction, measuring path (µm)

|

0.6

|

|

Measuring speed (mm/s), Z axis

|

0.1 to 50

|

|

Positioning speed (mm/s), Z axis

|

0.1 to 50

|

|

Straightness deviation / total measuring path (µm)**, X axis

|

0.3

|

|

Perpendicularity X/C axis, measuring path (µm)

|

0.3

|

|

Positioning speed (mm/s), X axis

|

0.1 to 50

|

|

Measuring speed (mm/s), X axis

|

0.01 to 50

|

Applications

valuation of roundness, radial runout, axial runout, concentricity, coaxiality, total ronout, cylindricity, straightness, parallelism, perpendicularity, pitch, flatness, conicity, line profile, position (DIN ISO 1101), taper form, diameter. Compact measuring volume, max load. 200 N Testing of ‘true parallelism’ by exceeding the workpiece center through the horizontal X-axis, result free from other measuring influences. Optimal for the increase of the tolerance range in production Fast roundness measurement with up to 200 rpm

Versions

MarForm MFU 110 FORM MEASURING MACHINE

- High-precision MFU 110 form tester with optical sensor and high speed C-axis

- MarWin evaluation computer

- Additional hardware as per Mahr standard as at time of delivery

- Windows-based operating system (Windows 7 Ultimate 64 bit)

- Mahr form and position evaluation software package

- Machine table base with integrated control unit

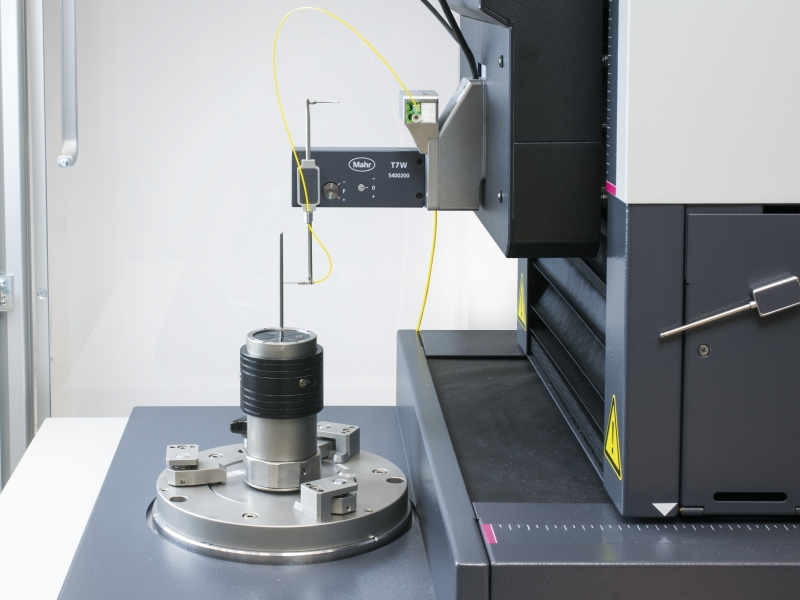

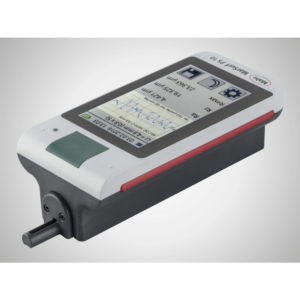

- T7W length measuring probe as motorized bidirectional probe, including standard probe arm with sphere Ø 3 mm

- with MarVision IPS 15 optical probe on request