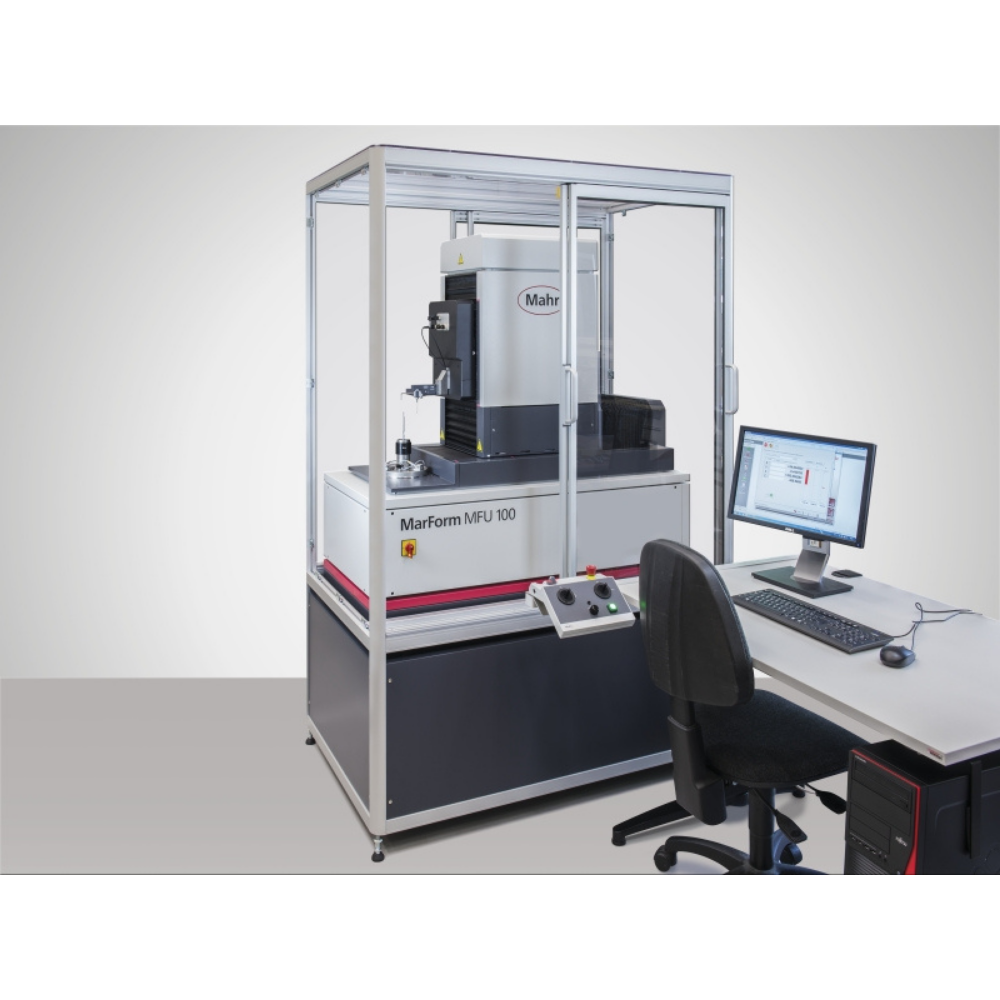

(EN) The journey from high precision measuring axes to competent measurements is often a long one that the MFU 100 has mastered completely. Only the MFU 100 has integrated reference elements for the real-time spatial compensation of geometric deviations, recording all profiles as high precision 3D coordinates.

For decades, MarForm measuring machines have been recognized for their accuracy and stability. The new MarForm MFU 100 was developed with the claims of testing the shape and position features of product parts in a one liter measuring volume close to the production area and at a reasonable cost. In doing so, it has taken our long experience into a new dimension.

Uzdot jautājumuTechnical Data

|

Roundness deviation (µm+µm/mm measuring height) *

|

0,01 + 0,0002

|

|---|---|

|

Roundness deviation (µm+µm/mm measuring height) **

|

0,02 + 0,0004

|

|

Axial runout deviation (µm+µm/mm measuring radius) *

|

0,02 + 0,0002

|

|

Axial runout deviation (µm+µm/mm measuring radius) **

|

0,04 + 0,0004

|

|

Centering and tilting table

|

automatic

|

|

Table diameter (mm)

|

180

|

|

Table load capacity, centered (N)

|

200

|

|

Speed (rpm) 50 Hz / 60 Hz

|

0.1 to 15

|

|

Straightness deviation / 100 mm measuring path (µm)**, Z axis

|

0.1

|

|

Straightness deviation / total measuring path (µm)**, Z axis

|

0.3

|

|

Parallelism deviation Z-/C axis in tracing direction, measuring path (µm)

|

0.6

|

|

Measuring speed (mm/s), Z axis

|

0.1 to 50

|

|

Positioning speed (mm/s), Z axis

|

0.1 to 50

|

|

Straightness deviation / total measuring path (µm)**, X axis

|

0.3

|

|

Perpendicularity X/C axis, measuring path (µm)

|

0.3

|

|

Positioning speed (mm/s), X axis

|

0.1 to 50

|

|

Measuring speed (mm/s), X axis

|

0.1 to 50

|

Applications

- Checking product parts for form and position features

- Recording of all profiles as high-precision 3D coordinates with real-time spatial compensation of geometric deviations

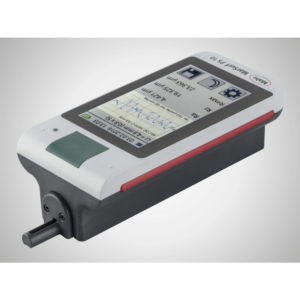

- Scanning of surfaces, roughness evaluation

- Scanning and evaluation of contours and shapes

Versions

- optionally also MarForm MFU 100 WP with optical sensor interchangeable with T7W (motorized)