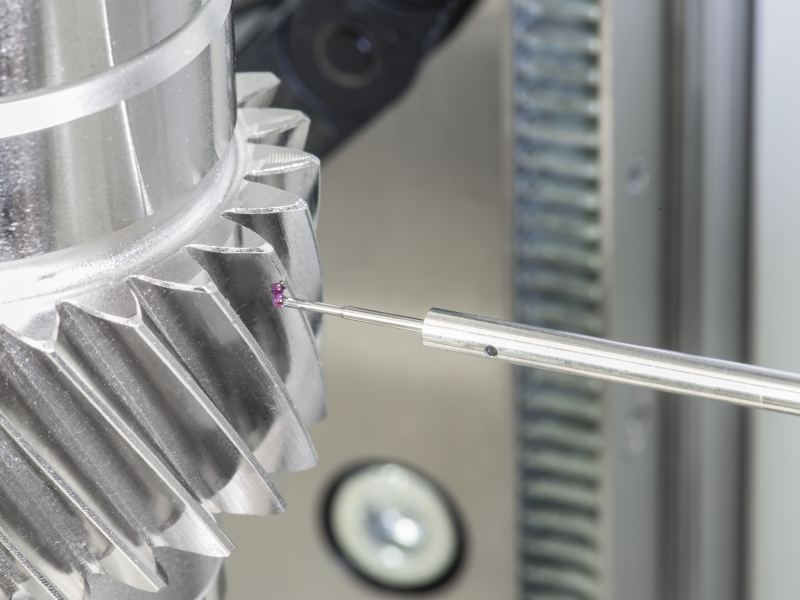

(EN) MarShaft MAN is a universal, modular shaft measuring instrument for the fast and flexible measurement of shaft-type testpieces.

Uzdot jautājumuTechnical data

|

Diameter error limit (X) (µm)

|

(0.8 + L/100) µm, L (length) in mm

(at 20°C ± 1°C on reference standard) |

|---|---|

|

Drives

|

manual

|

|

Lens

|

|

|

Length error limit (Z) (µm)

|

(3 + L/100) µm, L (length) in mm

(at 20°C ± 1°C on reference standard) |

|

Angle resolution (°)

|

0,001

|

|

Measuring range diameter (X) (mm)

|

120 or 220

|

|

Workpiece weight (max.) in kg (text)

|

20 / 60

|

|

Length/diameter resolution (mm)

|

0,0001

|

|

Measuring range length (Z) (mm)

|

400 / 800 / 1200

|

Applications

Typical workpieces:

- Crankshaft, camshaft, gear shaft, rack, axle journal, hollow shaft, drive shaft, turning parts

Typical measuring tasks:

- Length, diameter, radial run-out/axial run-out

Other measuring tasks:

- Distance, recess width, depth, increment, recess diameter, roundness, taper, radius, position of cross-holes, and much more

MarCheck for MarShaft MAN

MarShaft MAN Manual tactile shaft measuring machine

MarCheck is a new, compact measuring and evaluation unit for manual MarShaft MAN shaft measuring machines, featuring intuitive controls and an excellent range of functions. The minimal training input that is required means that the instrument can be used straight away, saving time and money. The large, easy-to-read monochrome LCD display (240 x 160 dots) can display up to three measuring channels at the same time. The individual measuring channels are activated automatically on the display when measuring with the corresponding measuring axis. The measuring direction is displayed. The MarCheck comes as standard with three measuring channels, for two linear measuring axes (Z and X) and one rotational measuring axis (C), which if necessary can be reconfigured to a linear measuring axis (R). The precision measuring spindle (C-axis) is controlled by MarCheck and switched on and off automatically for radial run-out and roundness measurements.

Performance features

- Large, easy-to-read monochrome LCD display (240 x 160 dots) with backlight

- 3 measuring channels (Z-axis, X-axis, and C-/R-axis)

- Numeral size approx. 13 mm

- 1 USB interface for max. 3 GB USB stick

- 1 USB interface for PC (optionally RS232 interface, data analysis in Excel or MarCom software) or software installation (updates)

- Can be connected to an inkjet printer

- Roundness and radial run-out measured with the DMS 120, no additional R-axis required

- Automatic adoption of measuring values on reaching the non-user specific measuring force

- Automatic adoption of calibration values from the individual measuring modules

Measuring and programming functions

- Evaluation of diameters, length dimensions, distances, taper, symmetry, center-to-center distance, roundness, axial run-out, radial run-out, concentricity, workpiece axis datum calculation, maximum/minimum function, preset function for datum points outside the workpiece.

- Teach-in programming, storage in MarCheck or on external PC or USB stick, printing to an external printer, internal storage of up to 40 measuring programs

Technical data

|

Grating constant |

option; 2 µm; 4 µm; 10 µm; 20 µm; 40 µm |

|---|---|

|

Interface data |

1x RS 232; 1x USB 2.0 type A, 1x USB 2.0 type B |

|

Incremental inputs |

T1; T2; T3 (sin/cos 1 Vss) 15-pin D-Sub |

|

Max. permissible travel speed |

0.2 m/s at G = 2 µm |

|

Input signal – cutoff frequency |

<100 kHz with sin/cos 1 Vss |

|

Standard languages |

German; English; French |

|

Measuring units |

mm/inches switchable in menu |

|

Frequency check response threshold |

100 kHz |

|

Resolution per measuring channel can be independently set |

0.0001 mm; 0.001 mm; 0.01 mm |